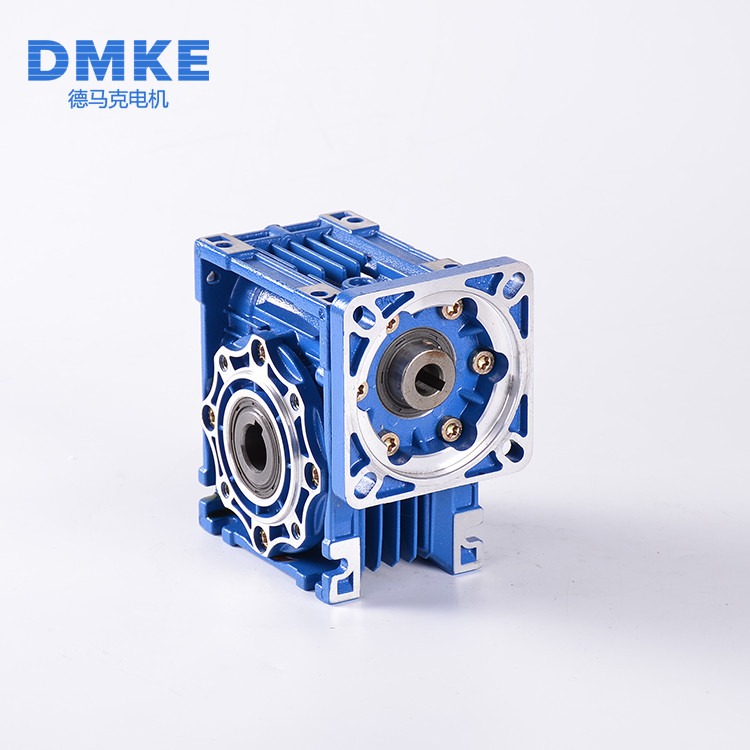

1.Occupied no space

The space requirement for the installation of the output shaft is considerably large while assembling motor or red of hollow type reducer may form a right angle with motor, thus facilitate miniaturize of the machine.

2. Self-locking

For the place require for minor holding force, save the cost of the baking device, such as in slope conveyor.

3. Fast stop

The ordinary gear reducer available in the market requires 5-10 seconds stop time. But NRV series product needs only 2-5 seconds to reach a state of still.

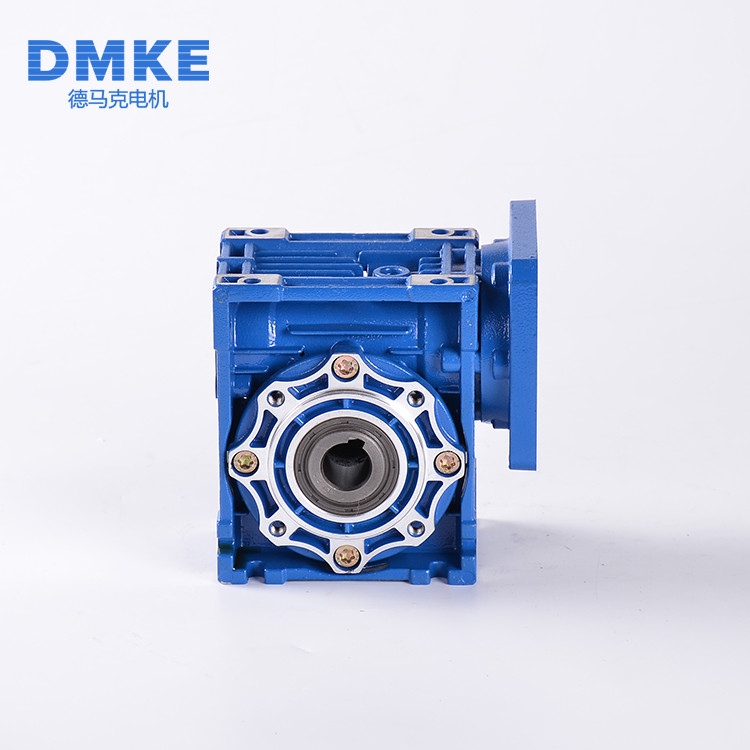

4. High accommodation

You may select from hollow shaft, uni-direction output shaft or dual output shaft, easy to modify, only one minute to complete the disassemble and assemble of that.

5. High safety

Use transmission different from the conventional method, no sprocket pulley is needed, no exposed transmission structure, reduce the possibility of the operator.

6. Good protection

Water, dustproof, the protection class P55 possesses, good isolation to dust and moisture.

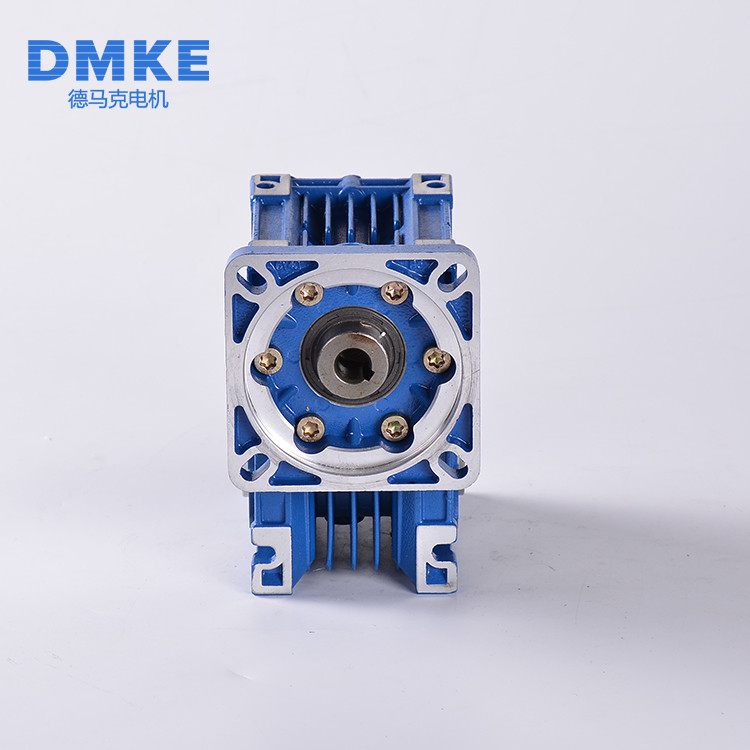

7. Allow multiple sides installation, no restriction in angle

8. Good cooling effect

One formation aluminum alloy for casing, quick heat dissipation extended life for the worn lever, worn gear, good durability (worm-casing during running is normal )

9. Easy maintenance

Different from the conventional mounting method, you need not the disassemble the sprocket, pulley but only dissemble mounting base of the reducer to complete the modification easily.

10. No restriction on brand

Match with 15W-20W panes or domestic product available in the market without further processing.

Gear ratio:7.5, 10,15, 20, 25, 30, 40, 50, 60, 80, 100

Weight without motor: 2.3kg